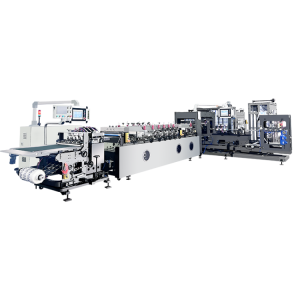

NCA300SJA Kanta Otomatis damel sareng mesin spout

Pamakean

Mesin 1?

Mesin jangkauan anu teu dihareup tina, giliran pasiéng magnét, penelem rolling roller panangan, nyintipkeun tempat anu nyepetkeun, berklarkeun (paningkatan tiris, barang-tanda priap tabel.

Kauntungannana

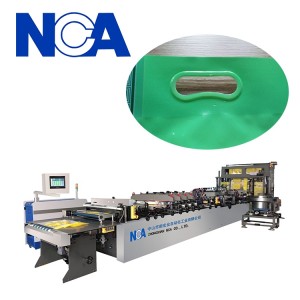

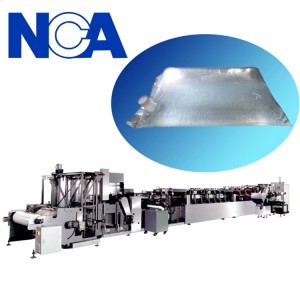

1.Welping nozzle, kantong damel mesin

Kantong Mandle Mark, Panyimpen (Refueling tanpa eureun)

Hésah Nyebogkeun: Ganda Ganda

Prosés damel

Mesin dimimitian tina unwinding, giliran nyedak batu magd magnét, penelihan rolling pencetakan disiikan, uap lapak panas, produk berteles, berlantukeun area leutik, formulir peedo.

Parameter mesin mesin

| 1 | Ventil | Film dina film angkatan |

| 2 | Kapon kapasitas: | Pupus kantong tunggal: Max35-40pcs / kantong mengeplo: Max 70-80pcs / mnt |

| 3 | Kecahan bahan | 0,06 ~ 0.15mm |

| 4 | Jenis spout | Béda macem-macem spout plastik leutik. |

| 5 | (Kecepatan pikeun kantong spout, laju khusus numutkeun ukuran anu kuos sareng bahan) | |

| 6 | Ukuran kantong: (l × w) | Suku tunggal: Max300 × 200MMDoelch kantong: Max150 × 100mm |

| 7 | Total kakuatan | Ngeunaan 25kw |

| 8 | Volelase listrik | Ac380V, 50Hz, 3p |

| 9 | Tekanan hawa: | 0.5-0.7MPA |

| 10 | Cai pendingin: | 10L / mnt |

| 11 | Mesin Modeu Gawé Mesin: | 950mm |

| Anggo operasi jangkung 850mm | ||

| 12 | Ukuran mesin (max): | L × w × H: 8200mm × 3500mm × 2000mm |

| 13 | Beurat mesin: | sakitar 5000kg |

| 14 | Warna mesin: | Kulawu (témbok) / baja steelless (jaga |